Vibration Spectrum Analysis Software

How does the vibration spectrum analysis software identify and analyze different frequencies present in a system?

The vibration spectrum analysis software utilizes algorithms and signal processing techniques to identify and analyze different frequencies present in a system. By performing Fourier transforms on the vibration data, the software can break down the signals into their individual frequency components, allowing for the detection of specific vibration patterns associated with different machinery conditions.

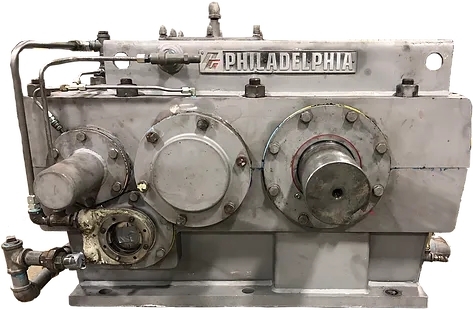

A Comprehensive Look At Industrial Gearbox Repair Tools and Standard Processes