Gearbox Load Distribution Analysis

How does gearbox load distribution affect the overall performance of a vehicle?

Gearbox load distribution plays a crucial role in determining the overall performance of a vehicle. Uneven distribution of load can lead to premature wear and tear of components, reduced efficiency, and even potential failure of the gearbox system. Proper load distribution ensures that each gear and bearing within the gearbox is carrying an appropriate amount of load, leading to smoother operation and extended lifespan of the system.

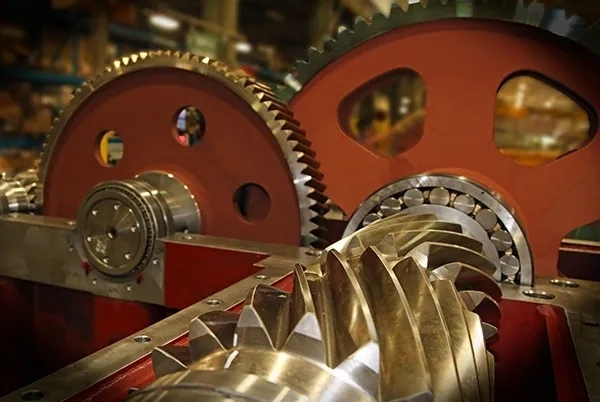

A Comprehensive Look At Industrial Gearbox Repair Tools and Standard Processes

Gearbox Bearing Preload Adjustment Techniques