Gearbox Performance Benchmarking Metrics

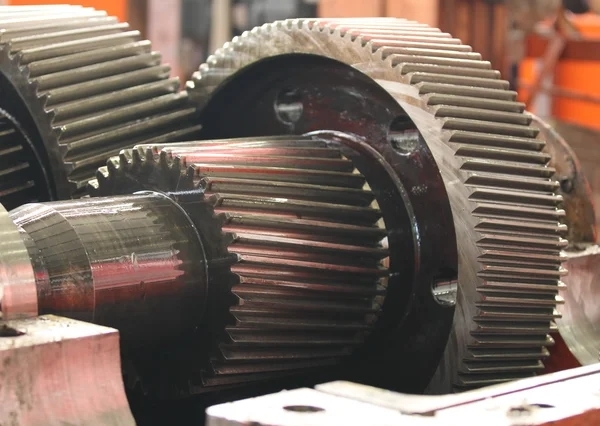

How does the gear ratio affect the performance of a gearbox?

The gear ratio plays a crucial role in determining the performance of a gearbox. A higher gear ratio can provide more torque at the expense of speed, while a lower gear ratio can increase speed but reduce torque. The selection of the appropriate gear ratio is essential to ensure optimal performance based on the specific application requirements. It is important to consider factors such as load capacity, speed, and power transmission efficiency when determining the gear ratio for a gearbox.