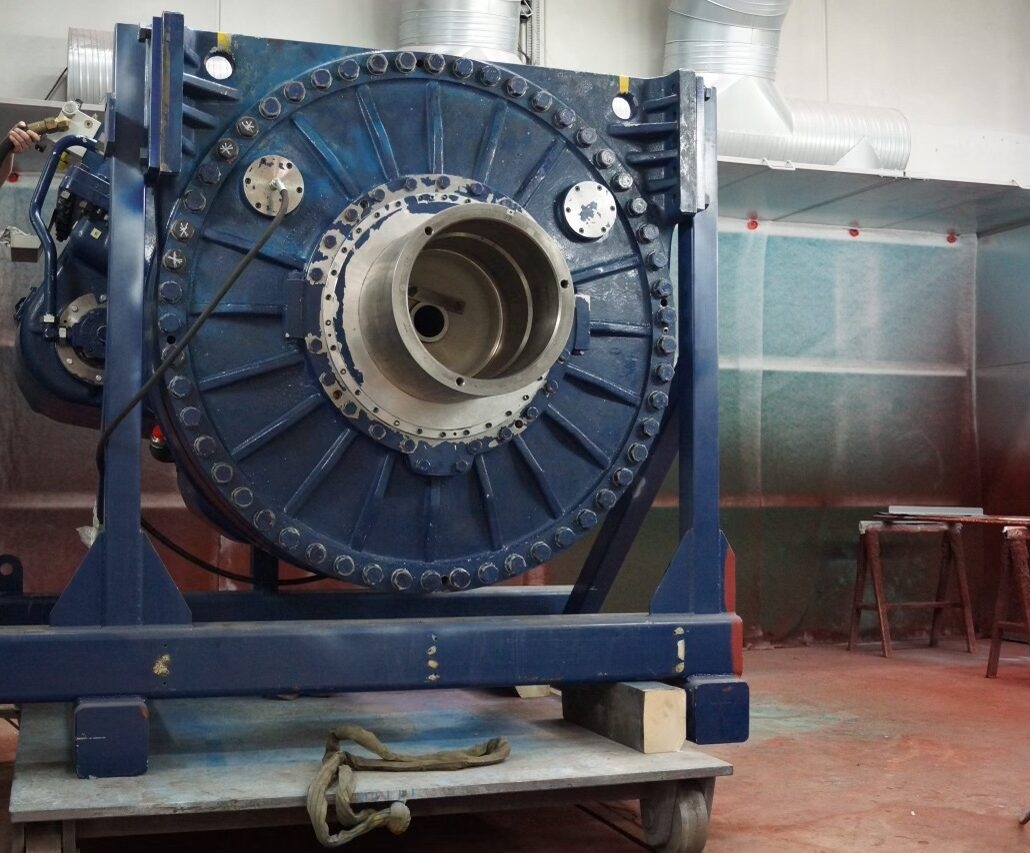

Gearbox Bearing Preload Adjustment Techniques

What is the purpose of adjusting gearbox bearing preload?

The purpose of adjusting gearbox bearing preload is to ensure that the bearings are properly loaded to prevent excessive play or tightness in the gearbox. By adjusting the preload, the bearings are positioned correctly to maintain the necessary clearance for smooth operation and to prevent premature wear or damage.