Gearbox Failure Root Cause Analysis

What are the common signs of gearbox failure in vehicles?

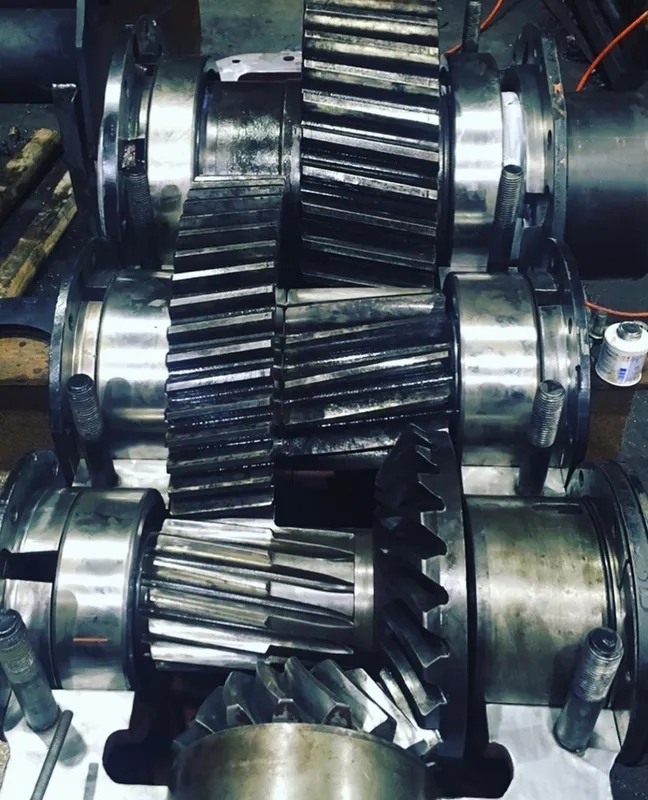

Common signs of gearbox failure in vehicles include grinding or whining noises while shifting gears, difficulty shifting gears, slipping gears, leaking gearbox fluid, and a burning smell coming from the gearbox. These signs indicate potential issues with the gearbox components such as gears, bearings, or synchronizers, which can lead to complete gearbox failure if not addressed promptly.

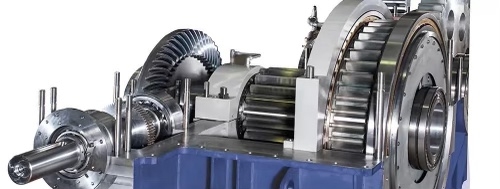

Gearbox Component Surface Treatment Options