Gearbox Efficiency Improvement Techniques

How can the use of high-quality lubricants improve the efficiency of a gearbox?

The use of high-quality lubricants in a gearbox can significantly improve its efficiency by reducing friction between moving parts, minimizing wear and tear, and ensuring smooth operation. High-quality lubricants can help maintain proper viscosity levels, prevent overheating, and extend the lifespan of the gearbox components. By reducing friction, the gearbox can operate more smoothly, requiring less energy input to function, ultimately leading to improved overall efficiency.

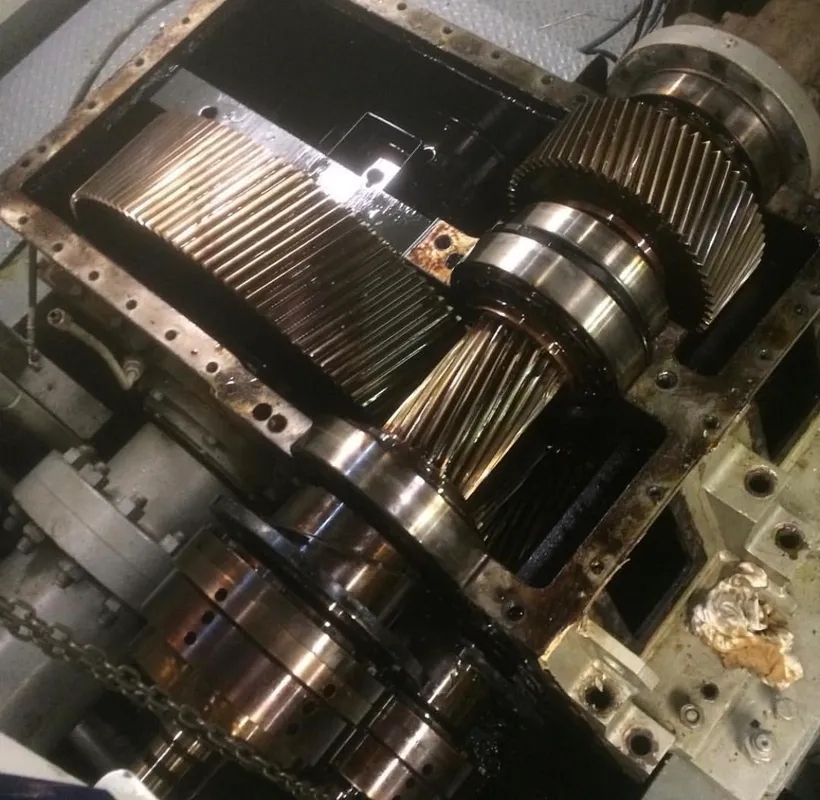

A Comprehensive Look At Industrial Gearbox Repair Tools and Standard Processes