Gear Tooth Contact Stress Analysis

How does the gear tooth contact stress analysis account for material properties such as hardness and elasticity?

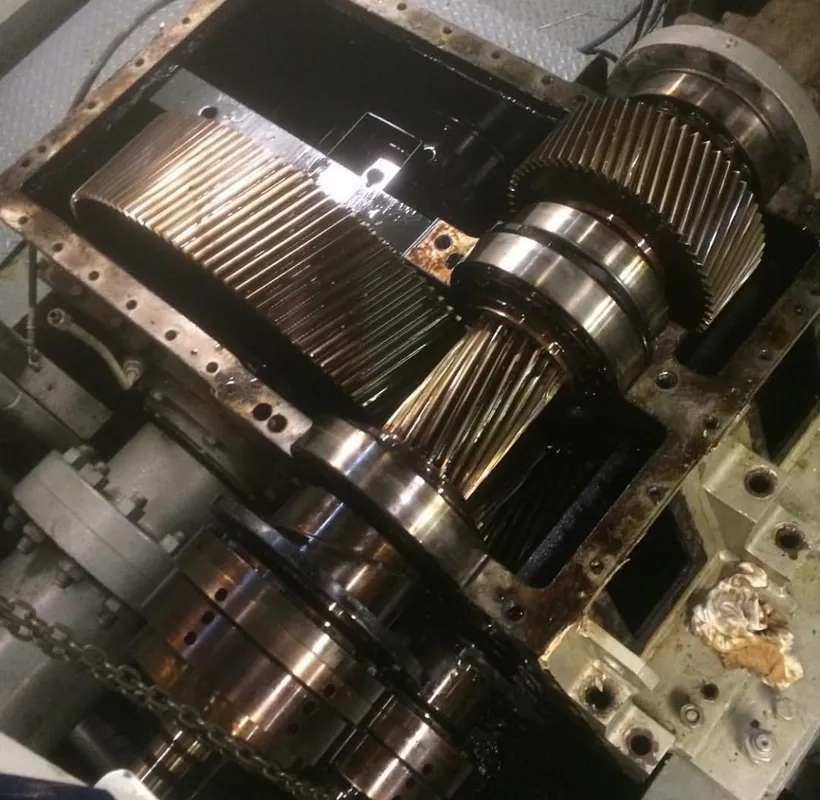

Gear tooth contact stress analysis takes into account material properties such as hardness and elasticity by considering how these factors influence the ability of the gear teeth to withstand the forces and pressures exerted during operation. Harder materials can typically handle higher contact stresses, while elasticity helps to absorb some of the impact and prevent premature failure. By incorporating these material properties into the analysis, engineers can better understand how the gears will perform under different conditions and make informed design decisions.