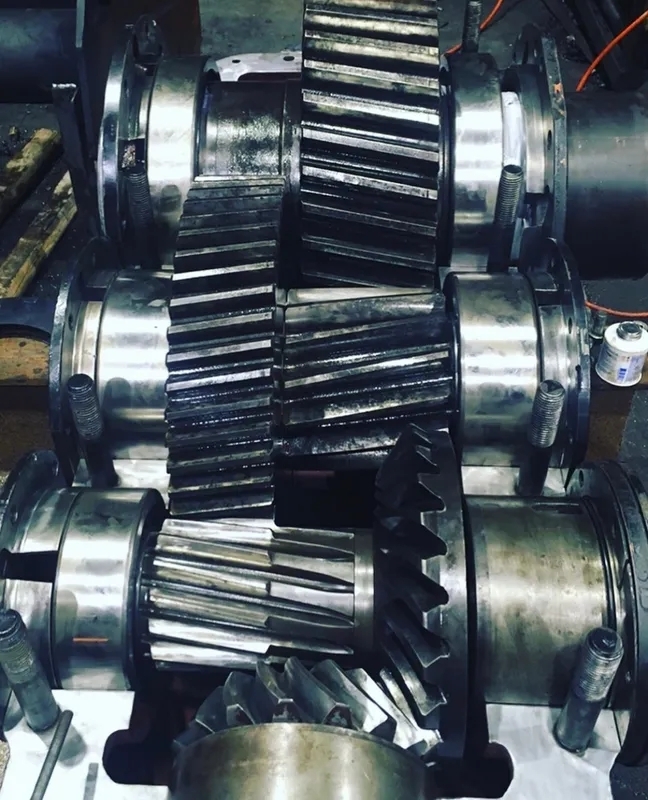

When determining whether a gearbox requires a complete overhaul or just a repair, technicians typically conduct a thorough inspection of the gearbox components, including gears, bearings, seals, and shafts. They will look for signs of wear, damage, or misalignment that could indicate the need for more extensive work. Additionally, they may perform diagnostic tests to assess the overall performance and efficiency of the gearbox. Factors such as noise, vibration, and fluid leaks are also taken into consideration when deciding on the appropriate course of action. In some cases, a simple repair, such as replacing a worn bearing or seal, may be sufficient to address the issue. However, if the gearbox is found to have significant damage or wear that could affect its functionality and longevity, a complete overhaul may be necessary to ensure optimal performance and prevent future breakdowns.