Gearbox Sealing Solutions Evaluation

How do gearbox sealing solutions help prevent leaks and contamination in industrial machinery?

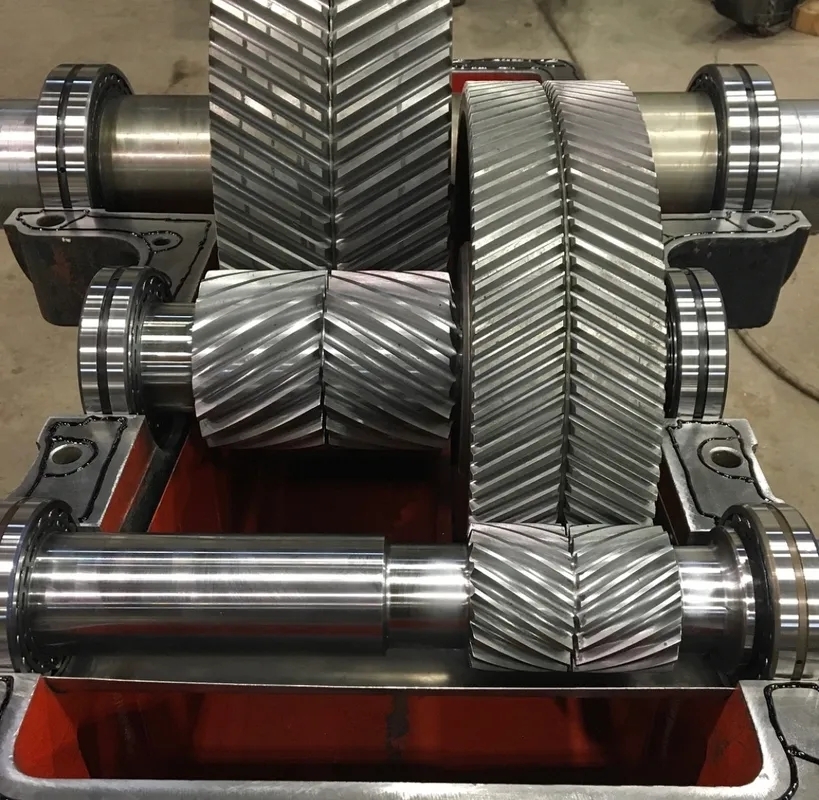

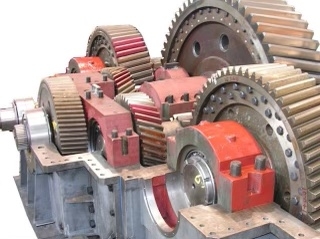

Gearbox sealing solutions play a crucial role in preventing leaks and contamination in industrial machinery by creating a barrier that seals off the gearbox components from external elements. These solutions are designed to withstand the harsh conditions often found in industrial settings, such as high temperatures, pressure, and friction. By effectively sealing the gearbox, these solutions help maintain the integrity of the machinery, prevent fluid leaks, and reduce the risk of contamination, ultimately prolonging the lifespan of the equipment.

Gearbox Noise Reduction Strategies