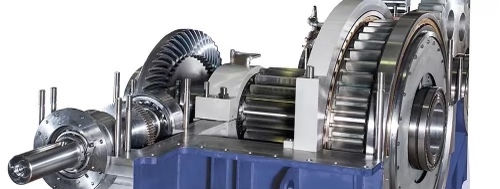

Gearbox Component Lifetime Prediction Models

How do material properties affect the lifetime of gearbox components?

The material properties of gearbox components have a significant impact on their lifetime. Factors such as hardness, strength, and fatigue resistance can determine how well a component will withstand the stresses and strains of operation. For example, using high-quality materials with excellent wear resistance can prolong the lifespan of gearbox components by reducing the likelihood of premature failure due to friction and wear.

Gearbox Failure Mode Effect Analysis (FMEA)