Gearbox Maintenance Training Programs

What are the common maintenance tasks involved in gearbox maintenance training programs?

Common maintenance tasks involved in gearbox maintenance training programs typically include inspecting gears for wear and damage, checking and adjusting gear clearances, replacing seals and gaskets, monitoring oil levels, and performing regular oil changes. Trainees learn how to disassemble and reassemble gearboxes, as well as how to properly torque bolts and fasteners to ensure proper functioning of the gearbox.

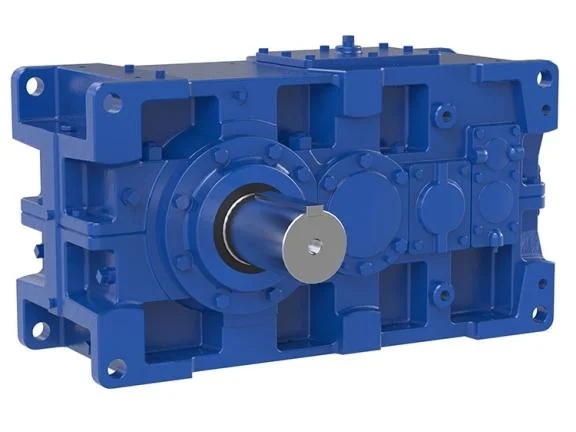

A Comprehensive Look At Industrial Gearbox Repair Tools and Standard Processes

Gearbox Housing Material Selection Criteria